Daika has met many challenges such as simplification of operating and cleaning procedures to meet client requirements.

As a result, we have gained client confidence in many industrial fields.

Examples include the products we have recently delivered shown below.

Contents may be updated as needed. We hope this information will be informative for those considering our products.

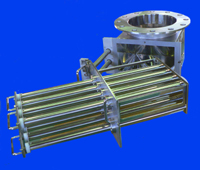

Manual drawing DIA-SLUR;DSC-40

Features;

This separator is easier to clean than the simple cleaning DIA-SLUR for viscous liquids. Magnets are cleaned without being removed from the line, however, so a separate line must be installed for cleaning with cleaning water (agent) on the line.

Cleaning procedures;

This is an ordinary line while running. To clean, raise the upper handle to remove magnetism and drop particles adhering to the separator in the line.

Use at client's factory;

Removal of fine iron particles from inorganic slurry.

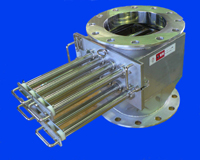

Automatic cleaning DIA-SLUR;DSC-40A

Features;

This separator is easier to clean than the simple cleaning DIA-SLUR for viscous liquids. Magnets are cleaned without being removed from the line, however, so a separate line must be installed for cleaning with cleaning water (agent) on the line.

Cleaning procedures;

Basic operations are the same as for the above manual drawing, but this separator is cleaned remotely automatically, not manually. Basically, the client is asked to make electrical connections, but we are ready to do such work.

Use at client's factory;

Removal of fine iron particles from pigment solutions.

Simple cleaning DIA-KONNER for pneumatic feeding;

DCH-125AQ

Features;

This separator was developed for pneumatic transfer of powder and designed to withstand a pressure of up to 0.1 MP. Vertical and horizontal are available and interchangeable.

Use at client's factory;

Removal of fine iron particles from pneumatic flour feeding line.

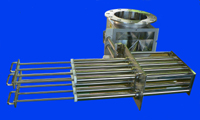

Inclined simple cleaning DIA-KONNER;DCS-150AQ

Features;

This separator is designed to improve cleaning of conventional inclined simple cleaning separators and safety in handling high-power magnets.

Use at client's factory;

Food industry: Removal of fine iron particles from starch.

Chemical industry: Removal of fine iron particles from silica and acrylic powder.

Inclined automatic cleaning DIA-SELF;DCS-200AMS

Features;

The inclined simple cleaning type evolved into an automatic cleaning separator.

Use at client's factory;

Removal of fine iron particles from silica powder.

Automatic cleaning DIA-SELF;DAS-200AMS

Features;

This machine uses a 3-stage (3 + 2 + 3 components) AMS and uses an air blower to remove residue on the tube in cleaning mode and individual structures for each stage to clean the details in periodic inspection. It is designed for on-site requirements.

Use at client's factory;

Removal of fine iron particles from sealing materials.

Simple cleaning DIA-KONNER;DCH-200AQ

Features;

This separator is designed to improve conventional simple cleaning and safety of handling of high-power magnets.

Use at client's factory;

Removal of fine iron particles from resin material powder.

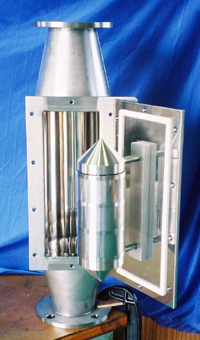

DIA-CANON for high pressure;DKP-90

Features;

This separator was developed for a withstand pressure of 0.2 mPa higher than that of conventional separators, 500 Pa. It realizes magnetic force of 1,300 mT (nominal, on surface). A conventional rotating (manual) magnet is used for ease of cleaning.

Use at client's factory;

Removal of fine iron particles on pneumatic flour feeding line.